The choice of a hacksaw for wood

We independently test the products and technologies that we recommend.

Types of saws

To begin with, let's define the existing types of wood saws. This category includes:

|

- standard (with a wide long canvas). It is used when a straight rough cut is required, for example, to cut a board, billet or beam. To ensure that the canvas does not deviate from the initial marking during the cutting process, a joiner's chair may be needed;

|

- narrow or vykruzhnaya (with a narrow canvas). It is intended for cutting wooden blanks, the thickness of which does not exceed 8-10 cm, through cuts and sawing out radius parts made of wood, chipboard, MDF in furniture production. Also perfect for pruning trees;

|

- beam (with a stretched narrow web), a manual analogue of an electric jigsaw used for precise longitudinal cutting at any angle. Such a saw is quite fragile due to its design, therefore it requires careful handling;

|

- obushkovaya (carpentry variety: pasovochnaya). It has a thin cloth with a small tooth, a stiffening rib (rim) and a handle located at 45 °. Designed to create shallow longitudinal and transverse cuts and studded joints in wooden surfaces of any thickness. Often requires the use of a chair;

|

- two-handed. An analogue of a classic hand saw with a double-sided grip for simultaneous work of two people. It is used for cutting large logs and blanks. It has high performance.

|

A rare type of two-handed saw is a pocket chain saw, which, due to its simple design, allows one person to work with it. A log or branch is covered by a chain, which is driven by two handles.

Selection criteria

To decide which of the saws to choose, you need to find out what kind of work it will be intended for: carpentry or carpentry. In the first option, you will need to saw cleanly and carefully, mainly dry wood. The second option just has to do the job quickly. The purity of the cut and the condition of the wood do not play a role here, only the size of the workpiece is important.

In this regard, the further choice of a saw on wood occurs according to the following criteria:

- the material and dimensions of the canvas;

- configuration and material of the handle;

- number of teeth per 1 inch;

- tooth shape and size,

- the cost and brand of the product.

Material and dimensions of the canvas

A high-quality blade for a saw is made of tool / alloy steel. The higher its class, the more durable and performant the tool is. Stainless steel with a hardness of 45 units on the Rockwell scale (HRC) is most often used for saws. You can also find combined saws in which the blade is made of HRC 45 steel, and the teeth are made of HRC 55 or 60.

The blade of the saw should be perfectly smooth. Bend it to a noticeable tension and release it, then check for bending. It should not exceed 2 mm. The saw teeth should be the same in size, shape and layout.

In addition to conventional saws, saws with hardened teeth are widely used.

|

Such a tooth serves for a very long time, a saw with it will last for many years, but when it blunts, it will have to be thrown away. Sharpening a saw on wood with a red-hot tooth is not made, although you can try, suddenly the teeth are not really red-hot, but simply painted black, which is often the sin of manufacturers of frankly cheap saws.

As for the length of the web, it directly affects the size of the workpiece being processed. Saws with a cloth up to 30 cm are suitable for working with small boards and slats. But to cut a log, you will need a saw with a working surface of 40 cm.

As for the width, it can vary between 10 – 20 cm. This parameter is not very important, but it is worth considering that too wide a canvas will get stuck in the cut.

Handle

Each master selects the handle according to individual preferences. Most low-cost saws have handles made of plastic, top models are rubberized. The material from which the handle is made is less important, since it is still recommended to work with gloves, but it is better if it is elastic and non—slip, and the handle has a comfortable grip.

Pitch and shape of teeth

The pitch and, accordingly, the size of the teeth is measured by the TPI value, which determines their number per 1 inch of the length of the web. It is better to cut thick bars with large teeth with a TPI from 3 to 6. At the same time, the cut will be rough, and the speed of cutting is high. With boards of medium thickness, a canvas with a TPI from 7 to 9 will cope faster. For thin carpentry, a saw with a step from 2 to 2.5 mm or 10 – 13 TPI is more convenient. Here the cut will be as clean and neat as possible.

|

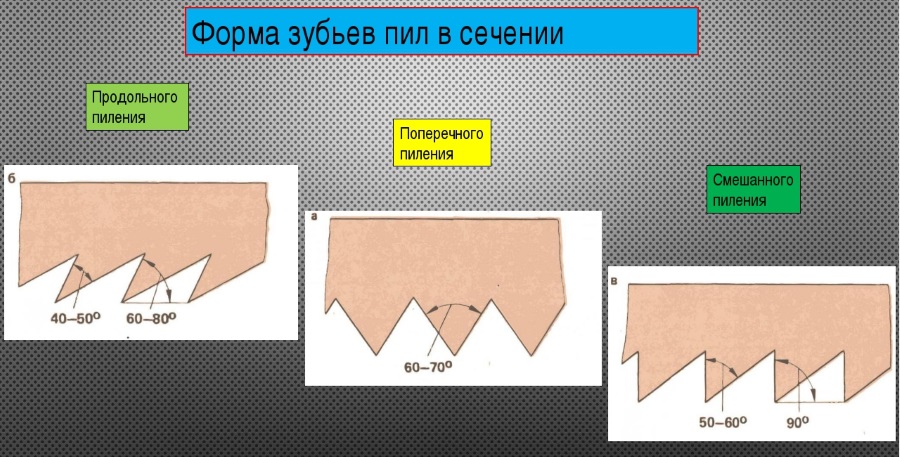

As for the shape of the tooth, the classic is considered triangular. A saw with such a tooth is usually used for cross-cutting (when it is necessary, for example, to cut a log in half across the fibers). The trapezoidal shape of the teeth is used in longitudinal (cutting, sampling in a bar) and mixed sawing and differs in the degree of the angle of inclination of the tooth (see figure).

|

Sharpening and wiring

|

How to sharpen a saw on wood with an ordinary tooth? Relatively simple. To do this, you do not have to resort to the help of professionals, but you will only need a pair of hands and a triangular file with a small notch, which has a special marking of an accident, which means "for the point of saws". Just a few neat, gentle movements, and the tooth will become sharp again. But if you need to sharpen the saw quickly, you will need abrasive wheels.

A special device is used for wiring the teeth. It is called "wiring". If you look at the canvas up close, you can see that its teeth are alternately separated in different directions at the same distance.

The wiring removes sawdust and sets the width of the cut. In turn, the wider it is, the more difficult it is to cut, but the diluted canvas “walks” less, and the cut is more accurate.

The width of the wiring is considered optimal if it is 1.5 – 2 times the thickness of the web for hard rocks, and 2-3 times for soft ones. It is important to remember that bending the teeth at the base is unacceptable. The bend should be made in the middle part of the tooth, otherwise it will break.

Cost and brand

And the last two criteria for choosing a high—quality saw are its price and brand. Saws from well-known brands are more expensive, especially when it comes to a tool with red-hot teeth. Here, top brands guarantee strict quality control of the steel used and advanced quenching technologies. The price of such saws is higher, but it pays off with a long period of trouble-free operation.

We choose the best scales for the home: from simple models for weight control to multifunctional body analyzers.

To date, the most popular sinks are made of ceramics, stone, glass and even stainless steel.

With a GPS tracker on your wrist, your child will always be under control.

From a digital model to a real thing in a couple of hours.

Music is an integral part of car rides.